Realizing Co-Packaged Optics technology! Photonics connecting the future

Top / Research and Development / Towards the realization of Photonics-Electronics-Convergence technology! The future connected What is a Reflowable MT Ferrule? ~ Development of MT Ferrule Compatible with CPO/OBO ~

As data centers evolve, optical connection technology is also advancing rapidly. In particular, the spread of next-generation technologies such as Co-Packaged Optics (CPO) and On-Board Optics (OBO) has created a demand for optical connectors with higher performance and improved heat resistance. To meet this need, Hakusan Inc. is developing reflowable MT Ferrule that perform more stably even in high-temperature environments than conventional MT Ferrule, and are expected to be the optimal optical connection solution for the optical engines of next-generation data centers.

What is reflowable MT Ferrule (MTHR)?

MT Ferrule are important components for accurately aligning Multifiber optical fibers and improving the connection performance of optical communications. They are particularly widely used as a core component of MPO (Multi-Fiber Push On) connectors. MT Ferrule are indispensable for supporting high-density wiring in data centers and communication infrastructure.

However, in recent years, the optical communications market has seen the development of new optical communications device technologies, such as CPO/OBO technology, which address the need to reduce power consumption. These technologies require the optical engine to be mounted directly on the board.

Therefore, optical connectors also need to be able to withstand the reflow process (the high-temperature environment during soldering). Conventional MT Ferrule had problems with dimensional changes and degradation of optical performance in high-temperature environments.

In contrast, Hakusan 's reflowable MT Ferrule (MTHR®) are designed to withstand a reflow temperature of 260°C while minimizing dimensional changes, especially fluctuations in the optical fiber holes.

Features of reflowable MT Ferrule (MTHR)

High heat resistant material

Reflowable MT Ferrule (MTHR®) use a material different from polyphenylene sulfide (PPS), which is the material used for conventional MT Ferrule. This allows the dimensional stability to be maintained even after a reflow process at 260°C. Furthermore, the durability is improved, providing stable optical performance even after repeated mating.

High-precision ferrule design

The positional accuracy (eccentricity) of the fiber hole in the ferrule is kept to 0.7µm or less to minimize the misalignment of the fiber core after reflow. Currently, Single-mode series is available in 12-Fiber, 16-Fiber and 24-Fiber configurations.

reflowable boots and caps

We have also developed reflowable boots and caps as dedicated accessories for reflowable MT Ferrule. In particular, the ferrule caps play a role in preventing contamination of MT Ferrule end face caused by flux vaporization during the reflow process.

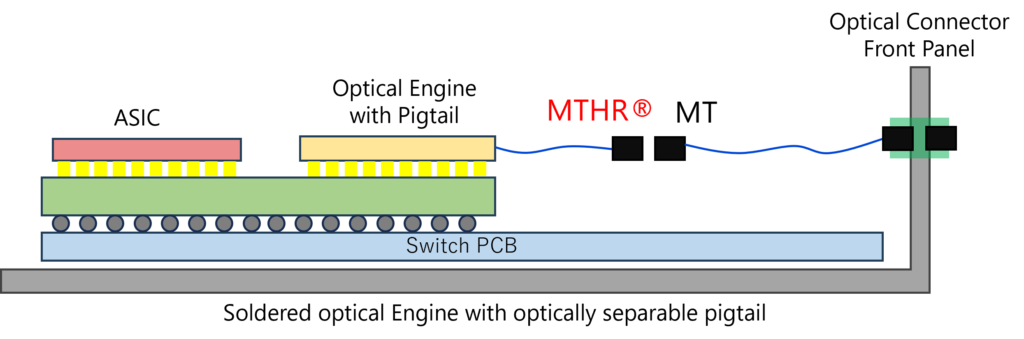

Potential use cases

MTHR® is intended for use with optical engines with optical fiber pigtails. In the case of optical fiber pigtails with reflow-mounted optical engines, as described in a technical white paper published by COBO*** in 2022, the connectors used there undergo the same mounting reflow process as the optical engines, and therefore must be reflow-resistant.

“One method of achieving this optical separation is for the OE to integrate a short length of fiber ending with an optical connector (i.e. a fiber pigtail, See Figure 3-2). Again, because the fiber pigtail is permanently fused to the OE, it too must be compatible with solder reflow temperatures.”

– Citing the Page 16 of ‘Design Considerations of Optical Connectivity in a Co-Packaged or On-Board Optics Switch’

The diagram was created by Hakusan based on "Design Considerations of Optical Connectivity in a Co-Packaged or On-Board Optics Switch."

***What is COBO?: The predecessor organization of the current Advanced Photonics Coalition. COBO is the abbreviation for Consortium for On-Board Optics, an industry group that develops specifications and industry guidance documents to enable the use of board-mounted optical modules in the manufacture of network equipment.

Internal test results

As a test in the Hakusan, the MT Ferrule is heated for 10 minutes in a temperature environment of 260°C, and the dimensional fluctuations of the before and after the temperature are checked, especially the amount of eccentricity of the fiber holes. The actual reflow process takes a few minutes at around 250°C, but since the actual conditions may differ depending on the company, we conducted a test in the above temperature environment. As a result, we were able to reduce the amount of fiber pore eccentricity after fluctuation to 0.7 μm or less.

Samples have already been supplied, and are being evaluated after optical fiber assembly according to each application.

summary

Hakusan 's reflowable MT Ferrule are an innovative optical connection solution for next-generation optical communication technology. Compared to conventional MT Ferrule,

- Stable in high temperature reflow environments

- Maintains high accuracy of fiber hole even after heating

- Affinity with CPO/OBO

With these features, it is expected to become the optimal MT Ferrule (Multifiber optical connection solution) for CPO/OBO technology. We are continuing to develop it in line with the evolution of optical communication technology.

If you are interested in learning more about this product, please contact us.

Upon request, we can share research and development information and provide samples.

Please feel free to contact us.