Challenge to ultra-precision resin molding - Contribution to large-capacity optical communication infrastructure -

Top / Research and Development / The Challenge of Ultra-Precision Resin Molding ~Contributing to High-Capacity Optical Communication Infrastructure~ /Development Story: The Birth and Evolution of MT Ferrule

Hakusan Inc. has been developing ferrules for over 30 years. An early developer who is still active today shared the story behind the development of MT Ferrule. From the story, we learned how the development of MT Ferrule began and what difficulties it overcame.

The beginning of development

The development of MT Ferrule was initiated by a request from NTT. Hakusan Inc. received technology licensing from NTT and was one of the first companies in the world to develop MT Ferrule. NTT is promoting the development of optical fiber technology in anticipation of optical communication becoming mainstream in the future, and the licensing of MT Ferrule manufacturing technology was an important step toward the spread and evolution of optical communication technology.

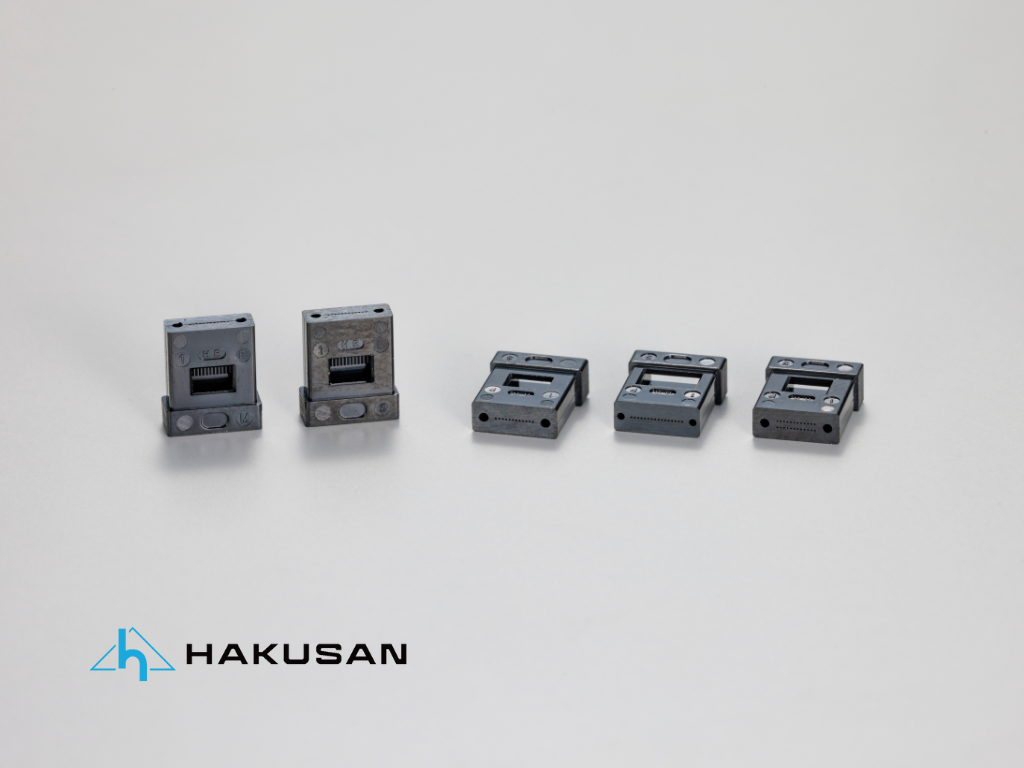

Initially, development proceeded with transfer molding using epoxy resin, but with a continuous process of trial and error, we faced many challenges from the start. Epoxy resin is highly water-absorbent, and we faced the problem of not being able to achieve physical contact. Furthermore, the transfer molding method has a long molding tact time and is costly, so we decided to switch to PPS (polyphenylene sulfide), which has low water absorption. PPS is a material with poor fluidity and is difficult to mold, but we worked with a materials manufacturer to develop the material.

Material Selection and Development

Special molds are required to mold PPS, and because there were problems with molding using standard molding machines, we developed a molding machine with special specifications. In addition, because PPS uses glass material, the mold is subject to severe wear, so we designed a dedicated mold to prevent this wear. In the early stages of material development, PPS had poor fluidity, making molding difficult. For example, there were material issues with the first prototype, such as parts of the material crumbling when polishing the ferrule, causing scratches on the fiber. Therefore, we worked with the material manufacturer to continue improving PPS.

Improvement of molding machines: Measures to prevent mold wear

Molding PPS requires high temperatures and pressures, which caused wear on molding machines and molds. To solve this problem, improvements were made to molding machines. Also, molds were subject to heavy wear and required frequent maintenance. In addition, improvements were made to the design of the molds. Also, wear could be prevented by properly managing molding conditions during molding.

Trial and error and success

In the early stages of development, there were problems with mold breakage and quality stability. In particular, mold breakage occurred frequently and had a significant impact on product quality. The mold design was reviewed and improvements were made to increase its strength. In addition, we worked on optimizing molding conditions, adjusting molding temperature and pressure, and succeeded in extending the mold's lifespan and stabilizing product quality. In addition, quality control was strengthened. Dimensional accuracy and appearance quality of the product were strictly checked, and measures were taken to minimize the occurrence of defective products. This improved the reliability of the product and increased customer evaluation.

Recognition of Major U.S. Telecommunications Carriers and Market Expansion

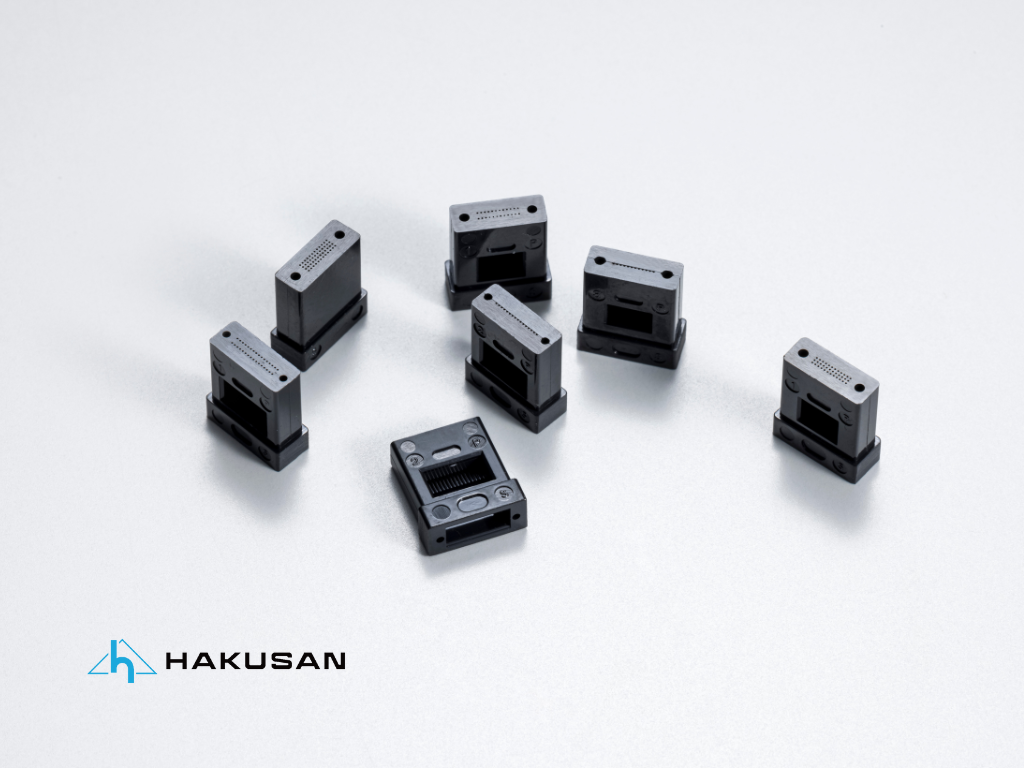

Ultimately, we succeeded in mass-producing 12-Fiber low-loss MT Ferrule, and the product was certified for use by a major telecommunications carrier in the U.S. The mold used at that time was the first product that would later become the basis for the molds for 12-Fiber low-loss MT Ferrule that are still being mass-produced today.

After receiving certification from the same telecommunications carrier, Hakusan began to attract even more customer attention. In particular, demand from U.S. telecommunications carriers and data center operators increased rapidly. This required Hakusan to expand its production capacity and strengthen quality control. To improve production efficiency while maintaining product quality, the company installed new production lines and employed automation technology. The company also focused on training its engineers, providing practical training to young technicians and allowing them to pass on the know-how of experienced technicians. In addition, Hakusan aggressively entered new markets. In particular, in the Asian and European markets, the company strengthened cooperation with local partners and promoted local sales. As a result, Hakusan 's MT Ferrule became highly regarded worldwide and the company's market share grew substantially.

Future developments and plans for the future

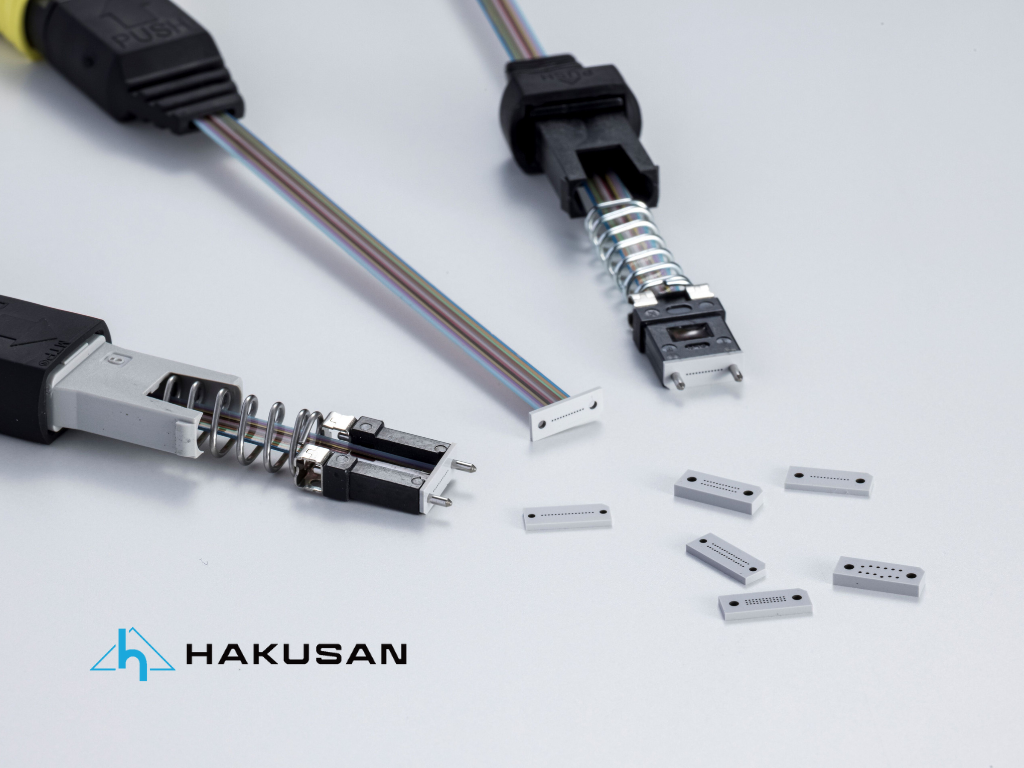

Hakusan plans to continue technological innovation of MT Ferrule. In particular, we are focusing on the development of low-loss ferrules and ultra-Multifiber ferrules, aiming for even higher performance. We are also conducting research and development of new materials, aiming to realize ferrules with excellent heat resistance and durability. Furthermore, as optical communication technology evolves, Hakusan is also working on the development of next-generation optical connection technology. In particular, we are focusing on the development of connection technology between optical fiber and optical waveguide, technology to reduce the optical connection space inside optical transceivers, and MT Ferrule that can withstand optical mounting boards (Co-Packaged Optics). Through this, we aim to realize a denser and more efficient optical communication system.

summary

The development of the MT ferrule was made possible after overcoming numerous technical difficulties, and behind it all was the persistent efforts and ingenuity of the developers. In particular, Hakusan's current success is directly linked to overcoming technical challenges one by one to balance product quality and productivity, such as the development of a dedicated PPS material and ingenuity to prevent mold wear. After receiving certification from a major U.S. telecommunications carrier, Hakusan expanded its production capacity and strengthened its quality control system, winning trust in the global market and currently holding the second largest share of the global market.

Behind these achievements is a developer who is still active in the field, and he is committed to developing the next generation of optical connectivity technology while at the same time fostering young engineers. His attitude of continuing to take on new challenges together with younger members symbolizes the inheritance and evolution of Hakusan 's technological capabilities, and is expected to further contribute to the optical communications market through the development of higher performance and more sustainable products in the future.

Please continue to pay attention to Hakusan 's challenges and growth.

Upon request, we can share research and development information and provide samples.

Please feel free to contact us.