What is a reliable welding method, Upset Butt Welding?

Hakusan Inc. handles Upset Butt Welder.

Upset Butt Welder are used in the manufacturing process of products that support social infrastructure.

In this article, what is Upset Butt Welding in the first place? I will explain.

Hakusan Inc. 's Upset Butt Welding is different from the standard pressure welding method, and is called the two-step upset method.In this article, we will explain the standard Upset Butt Welding.

(Explanation of Hakusan 's Upset Butt Welding will be introduced in the next article.)

What is Upset Butt Welding?

Upset Butt Welding is a method of joining two butted metal strips by heating them together and then applying pressure from each direction to the mechanically held metal strips.

It is widely used especially in the production of automotive parts and steel wire/electrical wire.

Principle of Upset Butt Welding

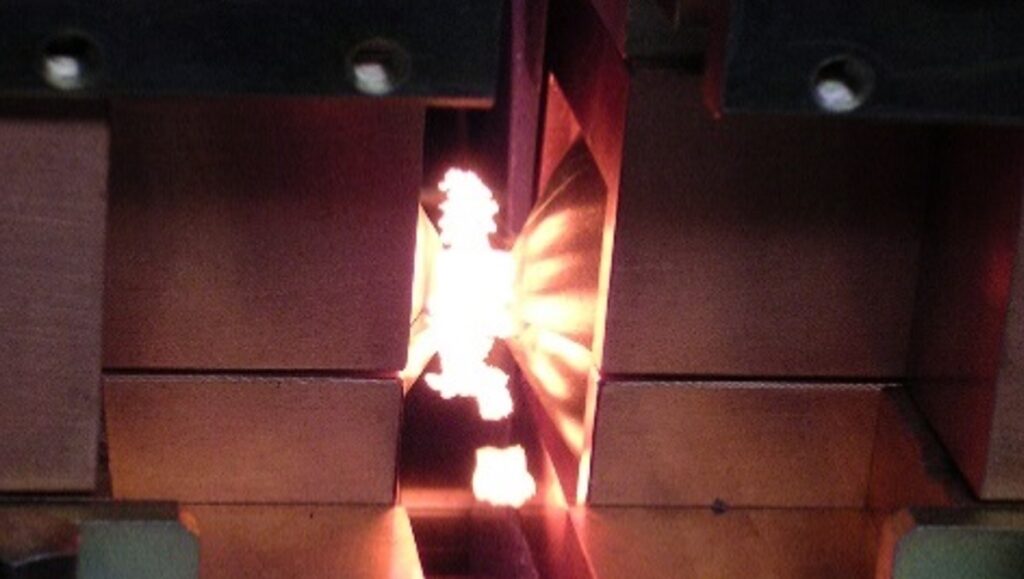

The joining method proceeds based on the basic principle of Upset Butt Welding. When the end faces of the metals to be joined are heated without melting and pressurized in the butting direction at the same time, the contact area between the metals increases and the atoms bond across the joining surfaces, resulting in a strong bond between the metals. .

What are the advantages of Upset Butt Welding?

Upset Butt Welding has many advantages. First, the joining is quick and efficient. This helps improve product quality and shipping speed by reducing time lags on the production line. In addition, unlike welding, Upset Butt Welding does not sandwich different metals, so the bonding strength is very good and the life of the product can be extended.

What is Upset Butt Welding process?

- Installation: Clamp the material you want to join.

- Heating: Heats parts to high temperatures in a short time.

- Pressure welding: Appropriate pressure is applied to hot parts.

- Processing: Processing of burrs, etc., formed on Upset Butt Welding part.

Adherence to these steps will result in an effective Upset Butt Welding.

There is a Upset Butt Welding Upset Butt Welder as a device that can accurately perform the hot pressure welding process.

-1024x678.jpg)

Where is Upset Butt Welding used?

Upset Butt Welding is widely used in various industries such as automobiles, aircraft, home appliances, medical equipment, and construction machinery. Due to its reliability and quality in these industries, Upset Butt Welding has become an indispensable joining method in the manufacturing industry.

In addition, it is mainly used for high-carbon steel wire rods, which are said to be difficult to connect, and copper wire rods, which require excellent connection performance as the speed of wire drawing machines increases.

It is also used for joining when producing electric wires that support social infrastructure.

summary

As can be seen from the above, Upset Butt Welding is a fast, efficient and reliable joining method. Due to these properties, the technology is widely used in many industries.

We hope that this article will help you understand a little more about Upset Butt Welding.

If you have any questions or inquiries about our company,

Please feel free to contact us.