職種紹介

PROFESSIONS

研究開発職/光接続技術

光に関する研究開発は主に次の2つに分けることができます。

- 超精密成型 光接続部品の設計、評価及び新製品開発、材料調査、試作対応等

- IOWN構想に必要な製品開発、光接続技術全般に関する新製品開発、材料調査、試作対応等

多心光コネクタ部品であるMTフェルールの開発・製造を20年以上続けてきた経験と実績から、日進月歩で進化する通信インフラに寄与する高精度、高密度な最先端のフェルール及び周辺技術を開発しています。

STAFF

-

MTフェルールの品質向上に注力。

1年目から既存製品、新製品まで

幅広く担当。各種MTフェルールの研磨、検査、測定、評価を行い、品質の改善と安定を目指しています。規格通りの精度を出すことは容易でなく、金型調整や成形担当者と相談しつつ過去のデータを参考に成形条件を変え、日々改善に取り組んでいます。元来、光通信とは異なる分野を学んでいたため、配属直後は苦労が多かったです。しかし回数を重ねるごとに質も速さも上達、1年目から既存製品、新製品まで幅広く任されるようになりました。

-

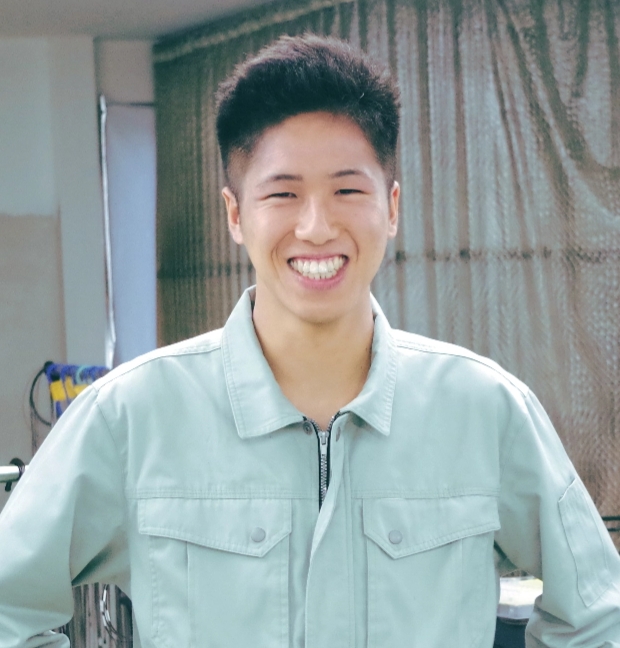

K・Tさん

研究開発職/光接続技術

必要な知識やスキル

学生時代は無機化学の研究を行い、入社後は新入社員研修として事業紹介や工場実習を受けましたが、配属されてからの仕事の厳しさは次元が違います。配属前は言われたことをしっかりと行えるようにと意識してきましたが、MTフェルールは「手順に沿って作れば出来る」という製品ではないため、状況を把握して考えることが重要です。現在は一つ一つの仕事に対して自ら考え実践し、間違いを正しながら進めています。さらに優先順位をつけて納期を守り、コスト低下につながるようにと深く考えるようになりました。

仕事のおもしろさ・成長を感じること

社会人になってから一人暮らしを始めましたが、終業後や休日は趣味や自己投資に時間を使えるため、とても充実しています。人事評価には自ら挑戦したいことを記すチャレンジ目標の項目があります。仕事で活用できるスキルのうち、私は機械設計の資格取得を設定しました。仕事とは切り離して同期と一緒に勉強する時間も楽しみの一つです。

配属当初から先輩方からはわかりやすく丁寧に教えていただいているため、将来後輩ができた時には私も同様に、一層わかりやすく伝えられるように支援していきたいです。

製造技術職/光通信製品

製造技術職では主力製品である多心光コネクタ、MTフェルールを生産するために金型調整、成形、洗浄、研磨、検査、評価といったことをしています。

MTフェルールは、髪の毛ほどの細さの光ファイバーを高精度につなぎ合わせてデータセンターへ光の情報を届ける、重要な役割を担います。0.1㎛単位で形作る製造技術力が白山の強みで、世界トップクラスの高い品質を実現するために繊細な注意と開発との連携が不可欠です。

STAFF

-

製造工程全般に精通する金型担当。

金型製造技術の要として活躍。入社当初は光通信製品の研磨や雷防護製品のライン作業を任され、その後自動車に関する精密成形品の加工、光製品の全製造工程を経て、現在は製造技術の肝となる金型担当として金型調整、成形、評価を行い、新製品の量産体制構築に取り組んでいます。

製造技術部にて多能工化を進めていますが、全工程を行えるのは現在私一人のため、臨機応変に動けるように職場での報告・連絡・相談は欠かせません。 -

K・Tさん

製造技術職/光通信製品

必要な知識やスキル

製品の出来栄えを左右する金型を担当していることから、規格通りの精度を出し安定生産につなげることが日々の課題です。サブミクロン単位の調整に成功法はなく、機械の状態や感覚をもとに「できるまで繰り返す」必要があるため技術よりも忍耐力が問われます。調整がうまくいっても部品の摩耗や型ずれが起これば製品不良につながるため、問題を発見した際にはすぐに職場で相談し対策に取り掛かります。すぐに実行に移せるものもあれば金型部品の設計変更までを行う場合もあり、その際には数か月かかるためスピードと優先順位を常に考えています。

仕事のおもしろさ・成長を感じること

当社の強みの一つは高精度、高品質を実現する製造技術力です。ネットワークの発展に伴い年々小型化、高密度化されていく製品に対してサブミクロン単位の精度を出すのは至難の連続です。光開発から量産に向けて引き受けた製品でも品質規格に合格するまでには数か月かかることもあります。そのような難易度から安定生産が難しく、世界でも類を見ないことに取り組み作り上げることができたときの達成感は格別です!

インターンシップ

INTERNSHIP

みずからが働くイメージを持てる!

インターンシップでは2つのプログラムを用意しています。

- 実務体験型インターンシップ:技術者が取り組む一連の流れをコンパクトに体験することができます。

- 実践型インターンシップ:学生の専門分野や関心に合わせて実業務の課題に取り組み提案まで行います。

仕事に活かせる力を試す、見つける!

実際の職場で技術者と肩を並べながら、仕事に近い形で取り組めます。ただ体験するだけでなく、主体的に多くのことを学べるように、事前に面談の機会を設けて学生の参加目的や知識・スキルを確認しています。ご経験やアイディアを活かせるプログラムになるよう進めていきます。

全国の学びたい学生大歓迎!

弊社ではニッチなものづくり、研究開発をしていることから全国各地に関連する研究室があります。そのため関心を持ってくれた学生には距離を越えて応えられるように、交通費や一部宿泊費、謝金等の手当を設けています。

参加学生からは「大学と企業の研究に関する違いを学ぶことができた」「レビュー時間と最終発表のディスカッションのおかげで研究への新たなアイディアが湧いてきた」といった声をいただいています。

採用フロー

FLOW

新卒採用フロー

-

01

会社説明会

説明や社員交流を気軽な雰囲気で行います。

丁寧にお伝えしますので、あなたに合う会社かご確認ください。 -

02

応募書類提出・WEB適性検査

次の書類をご送付ください。

エントリーシート、成績証明書、卒業見込み証明書 -

03

人事面談(希望者のみ)

面接への準備や改めて確認したいことなどありましたら、人事面談や電話、メールにてお応えいたします。

-

04

面接(2回)

面接では話しやすい雰囲気づくりを心がけています。

あなたの言葉でこれまでの経験や思いをお伝えください。

中途採用フロー

-

01

職場見学

社員から職場を見ながら具体的に仕事についてお話します。

しっかり見聞きし、あなたに合う会社かご確認ください。 -

02

応募書類提出・WEB適性検査

次の書類をご送付ください。

履歴書、職務経歴書 -

03

人事面談(希望者のみ)

面接への準備や改めて確認したいことなどありましたら、人事面談や電話、メールにてお応えいたします。

-

04

面接(2回)

面接では話しやすい雰囲気づくりを心がけています。

あなたの言葉でこれまでの経験や思いをお伝えください。

募集要項

RECRUITMENT INFORMATION

新卒採用、第二新卒

総合職

中途採用

生産管理│経験者歓迎

(石川/志賀町)

中途採用

品質保証│未経験歓迎

(石川/志賀町)

中途採用

生産を支える技術職

(石川/志賀町)

中途採用

プラスチック部品の製造オペレーター

(石川/志賀町)

中途採用

新設工場の製造オペレーター

(埼玉/所沢)

中途採用

グローバルマーケティング

(石川/金沢)

中途採用

経理・財務

(石川/金沢)

中途採用

光通信製品の開発

(埼玉/飯能)

中途採用

海外営業│経験者歓迎

(東京/池袋)