MTフェルール(MTコネクタ)の高精度化への挑戦

「独創と挑戦」により、新たな価値を創造する。

株式会社白山です。

今回の記事から株式会社白山・光開発部が手掛ける研究開発の内容をお届けします。

記事の連載テーマは、

「超精密樹脂成形への挑戦~大容量光通信インフラへの貢献~」です。

株式会社白山の主力製品である多心光コネクタ用部品「MTフェルール」。

「多心」という言葉がつくよう、

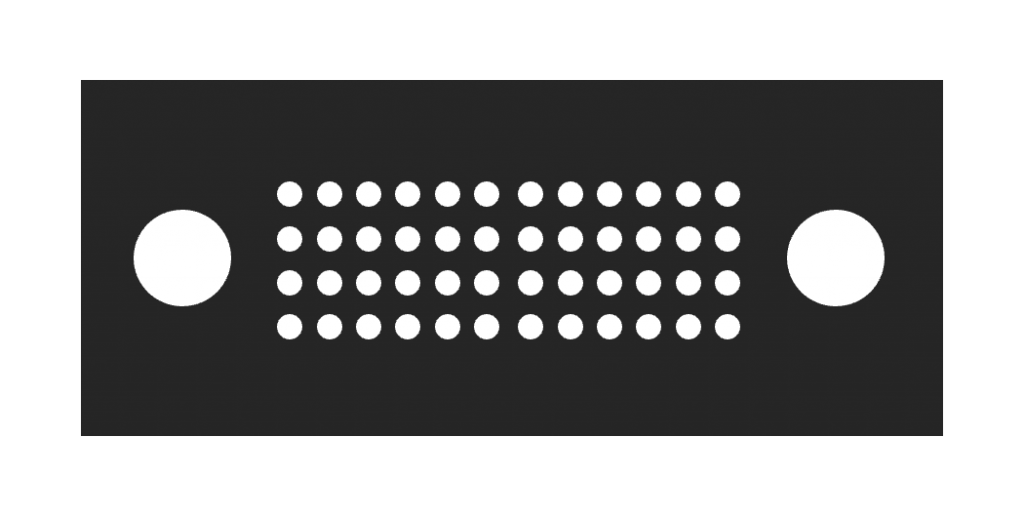

光ファイバーが挿入される孔が必要な数(8心以上)あります。

今回の記事では、時代の要求に合わせて、そのファイバー孔を最大限多く作る開発に取り組む様子をお届けします。

MTフェルール(MTコネクタ) とは?

MT(Mechanically Transferrable)フェルール。

光ファイバー同士を機械的に繋げる光コネクタと呼ばれるコネクタのキー部品。

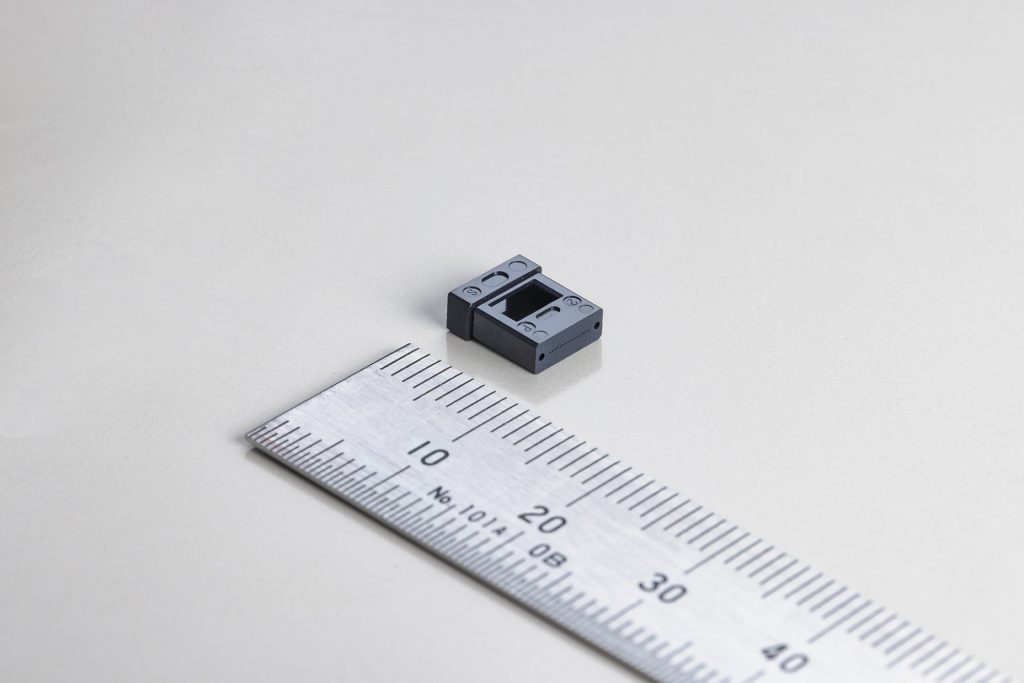

(長さ)8.0mm x (幅)6.4 mm x (高さ)2.5mm の樹脂(プラスチック)成形部品、コーヒー豆サイズのその部品の端面には、光ファイバーが無数に入るファイバー孔が開いています。

光ファイバーの直径は0.125mm、ファイバー孔はそのサイズの孔の大きさであり、その寸法精度はサブミクロン(0.1µm未満)の精度で出来上がっています。

株式会社白山は、1990年代前半からこの製品は開発し続け、今日では世界的に高いシェアを有しています。

使用されている場所は、多数のデータ処理が行われる国内外のデータセンターです。

あなたが普段使っているインターネット、

ソーシャルメディア(SNS)や動画閲覧、インターネット上でやり取りするデータ通信が無線ないし有線で最終的にはデータセンターに繋がっています。

この「MTフェルール」は、そのデータセンター内の光ファイバーケーブルを繋げているコネクタの部品なのです。

(一般家庭で見られる光ファイバーコネクタは1本の光ファイバーで成り立つ単心コネクタで接続されています。)

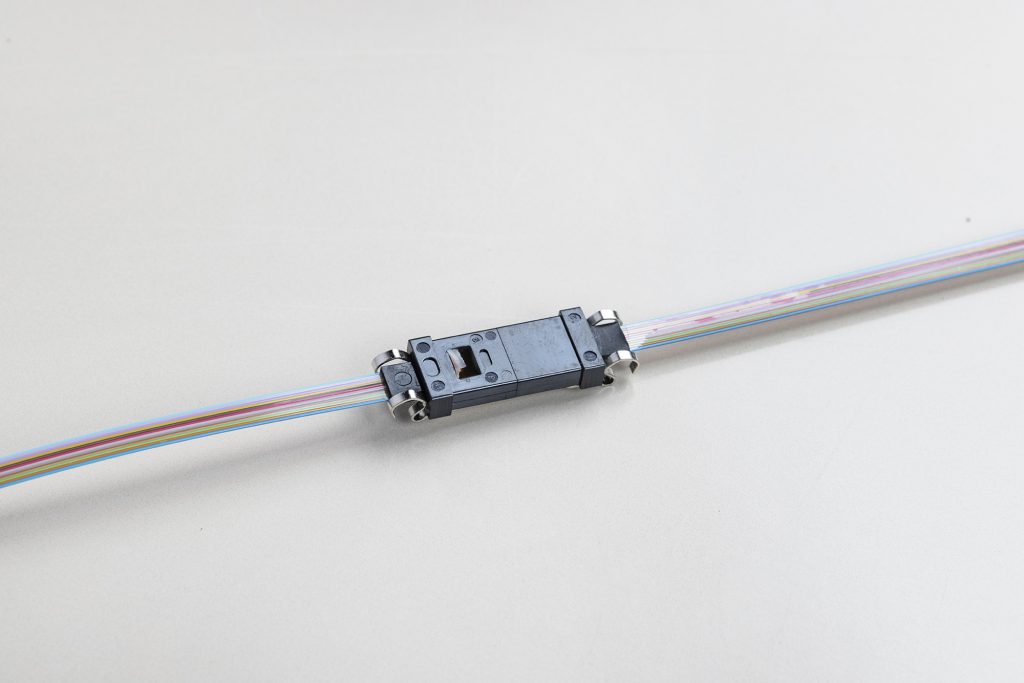

実際にはこのMTフェルールだけでは機能せずに、このフェルール同士を専用のクリップ(MTクリップ)と両端にあるガイドピン孔(ファイバー孔の横にある孔)にガイドピンを通し接続します。

このMTクリップ接続したコネクタのことをMTコネクタと呼びます。

ですが、今では単なるクリップによる接続ではなく、MPO(Multifiber Push-On)コネクタという多心コネクタのキー部品として、MTフェルールは全世界で利用されています。

ハウジングと呼ばれる外側の部品と内側にはバネとインナーハウジングという内側筐体の部品による構造となっています。

着脱性に優れた多心光コネクタとなっています。

ですので、MTフェルールとは、多心光コネクタ(MTコネクタ/MPOコネクタ)の基幹部品ということになります。

0.125mmの光ファイバーのコアをしっかりと位置合わせを行い、接続することで、安定した光通信を行うことができるのです。

そのため、光ファイバーを固定するMTフェルールが光ファイバーの接続精度を決めるため、MTフェルール自体は、非常に高精度な品質を要求されます。

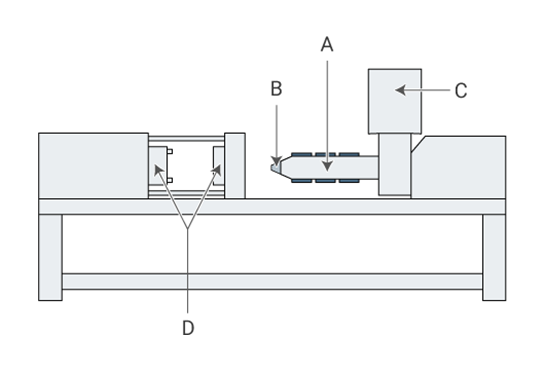

射出成形 とは?

MTフェルールは樹脂成形部品であり、その製造は射出成形によって行われます。

射出成形とは、ペレット状などの樹脂(プラスチック)を加熱しながら、製品の形を模した金型に溶かし流した後に、冷却し固めることで任意の形状の製品を取り出すことができる成形方法です。

射出成形で利用される樹脂は、加熱により可塑性が出る熱可塑性樹脂や加熱により硬化される熱硬化性樹脂があります。

また、射出成形は、下記のような射出成形機で行われています。

出典:キーエンス「なるほど!機械加工入門-射出成形とは」

株式会社白山は、熱可塑性樹脂を用いた射出成形によって、MTフェルールを製造しています。

高密度・高精度のMTフェルールの要求

熱可塑性樹脂を用いた射出成形によるMTフェルール。

多心光コネクタ自体が共通規格によって標準化されているため、MTフェルールの外形サイズもどのメーカーであっても基本的には同じです。

しかしながら、昨今では光コネクタやMTフェルールに要求される内容も多様になってきました。

背景としては、増加の一途を辿るデータトラフィック量に応じ、データセンターの規模も大きくなってきており、データセンター内部の光ファイバー配線も複雑になってきていることが挙げられます。

その影響で、処理できるデータ通信量を増やすために、利用される光ファイバーの本数も指数関数的に増加、光ファイバーコネクタが接続される通信デバイス(光トランシーバやネットワークスイッチなど)周辺の光コネクタの数も増えています。

あるデータセンターでは、

「コネクタの数を減らし、現場作業者の負担を減らしたい!」ニーズがあります。

その場合、ひとつのコネクタで接続できる光ファイバーを最大限多くしたいため、ひとつのMTフェルールに要求する光ファイバー孔の数が増える傾向にあります。

一方で、コネクタの集積度(コネクタに使う必要スペース)を減らすため、従来のMPOコネクタよりも小型のコネクタも出てきました。

株式会社白山では、コネクタの数を減らしたいニーズに対して、高密度かつ高精度のMTフェルールの開発に着手をいたしました。

シングルモード用超多心MTフェルールへの挑戦

着手したのは、シングルモード用48心MTフェルールの開発です。

MTフェルールのファイバー孔数は、8心、12心から24心と増えてきました。

最近では、光トランシーバの最新規格(400G:QSFP-DD, 800G:QSFP-DD/OSFP)に合わせ、16心インターフェースも市場に登場してきています。

MTフェルールには、光ファイバーの2タイプ(シングルモード・マルチモード)に合わせ、それぞれシングルモード用、マルチモード用があります。

光ファイバーは、その内部を伝搬する経路(モード)によって、シングルモード、マルチモードの2種類があります。

マルチモードは、複数のモードを伝搬でき、短距離・中距離の光伝送に使用され、シングルモードは、長距離・大容量の光伝送に使用されます。

この2種類の大きな違いは、光ファイバー内のコア(光が伝搬する中心部)の直径の違いにあります。

シングルモードとは、光が光ファイバーのコア(約9~10µm)を通り、ひとつの伝搬モードで成り立つモードのことです。

マルチモードとは、光が光ファイバーのコア(50µm又は62.5µm)を通り、複数の伝搬モードで成り立つモードのことです。

シングルモードファイバーのコアは、マルチモードファイバーのコアよりも、非常に小さいため、その接続精度もマルチモードと比較すると、非常に高いものが求められます。

そのため、接続に利用されるコネクタ及びコネクタ部品にも高い精度が要求されます。

株式会社白山では、シングルモード用MTフェルールは24心までの製品は量産しており、マルチモード用では32心MTフェルールまで対応しています。

しかし、MTフェルールの高密度要求(光ファイバー孔数の増加要請)に対応するため、シングルモード用32心および36心MTフェルールの開発を行いました。

開発完了が近く、直に量産へ移行される予定です。

それだけではなく、更なる高密度化の要求が高まり、昨年2022年から48心シングルモード用MTフェルールの開発に着手しました。

ファイバー孔数が多くなればなるほど、MTフェルールの射出成形の難易度は高くなりますが、求められる寸法精度はファイバー孔数の数によっては変わりません。

マルチモード用48心MTフェルールの経験はあるものの、それとは一線を画す寸法精度が求められるシングルモード用48心MTフェルール。

更なる大容量光通信インフラの実現に向けて、株式会社白山の超多心MTフェルールの挑戦が始まりました。

今後、この連載では、その挑戦の様子をお届けしていきます。

編集後記

ここまで読んでいただき、ありがとうございました。

株式会社白山の超多心MTフェルールへの挑戦、その背景について、お分かりいただけたでしょうか。私たちの便利なインターネットを支えるインフラにはこのような小さな部品が活躍しています。IoT、自動運転、AIなどこれからのITインフラ社会が実現するかどうかは、こういったひとつひとつの部品にかかっている。

とても遣り甲斐があることだと感じています。今後も株式会社白山の挑戦をお届けしていきます。

それでは、また、次の記事でお会いしましょう!

ご相談に応じて、研究開発の情報共有やサンプル提供が可能です。

お気軽にお問い合わせください。